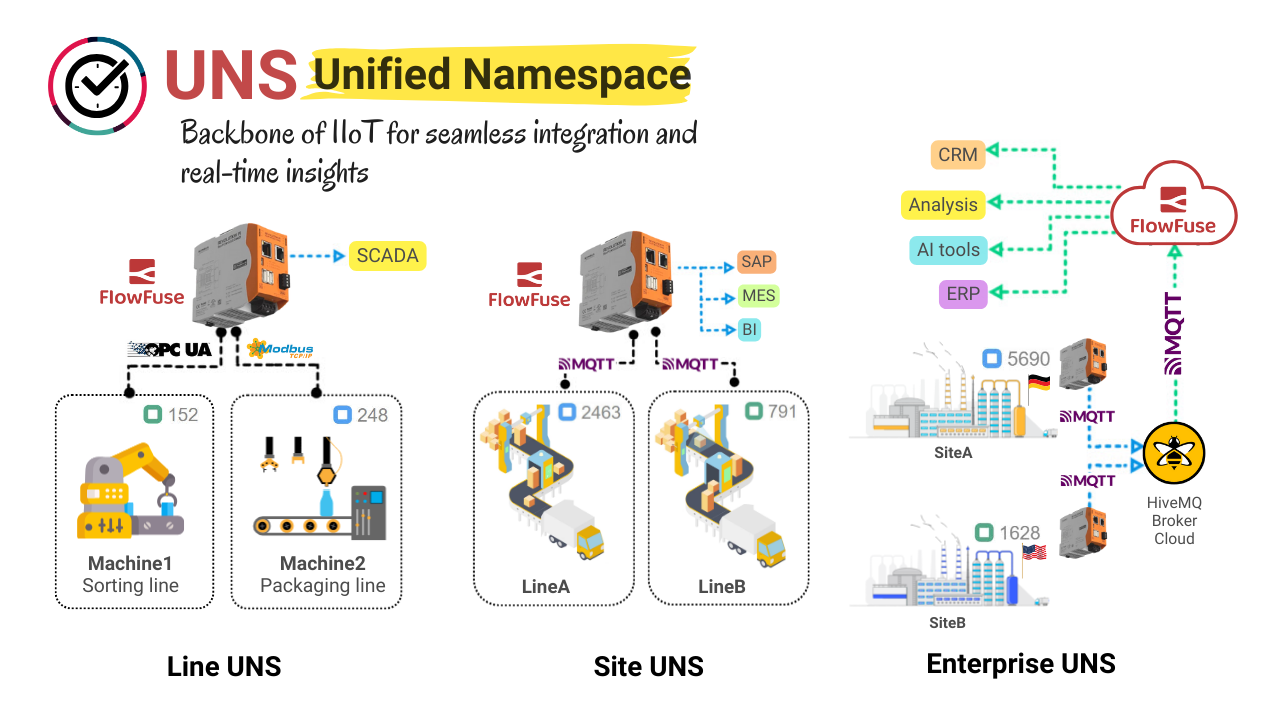

In the IIoT world, there is a need to build a robust and efficient data architecture, namely UNS (Unified Namespace). In this post, I am excited to share three examples that I created using FlowFuse highlighting the scope of Line UNS, Site UNS and Enterprise UNS.

Line UNS provides granular visibility into each production line. It’s about capturing and leveraging real-time data from every sensor, machine , and process to optimize operations. Line UNS enables precise monitoring, rapid troubleshooting, and predictive maintenance, directly impacting productivity and minimizing downtime

Using the FlowFuse agent installed on Revolution Pi, I successfully extracted my factory data 🏭 via OPC UA and MODBUS TCP/IP. Following data extraction, a Line UNS model was created on FlowFuse

As we zoom out to the site level, Site UNS integrates data across multiple production lines within a facility. It ensures cohesive operation, aligning production schedules, managing resources efficiently, and maintaining optimal energy usage.

To establish Site UNS, another Revolution Pi equipped with the FlowFuse device agent aggregates Line UNS data from each line via MQTT, forming the Site UNS.

Elevating to the organizational horizon, Enterprise UNS aggregates and harmonizes data across all sites and functions. It gives executives a 360-degree view of operations, financials, and market dynamics.

Finally, I succeeded in creating Enterprise UNS by aggregating data in my FlowFuse cloud instance from multiple sites through a HiveMQ Broker operating in the cloud. Having UNS on the cloud makes it easily scalable, enhances accessibility, enabling users to access the UNS from anywhere.